A long-term strategy for manufacturers adopting industry 4.0

It’s not uncommon for a factory to operate several generations of the same type of production equipment within a single factory. Except for extremely large companies with very deep pockets, most companies can’t afford to retool very often and must add their equipment in segments based on a long-term capital plan and in accordance with […]

What is Takt Time? How to calculate and reduce this key metric

The Industrial Internet of Things (IIoT) is transforming how manufacturing companies measure and improve processes. By using a machine data platform, companies can rapidly realize fast ROI and unprecedented improvements in efficiency and productivity. But industrial IoT and machine data platforms alone aren’t magic wands that can be waved to create new value. While they […]

Lean manufacturing: The Principles, Wastes, Benefits, and Tools

What is Lean Manufacturing? Lean manufacturing is a philosophy founded on a strategic approach to continuous improvement and sustainability through the holistic elimination of waste and inefficiencies throughout an organization. Lean manufacturing is more than following a set of rules—rather, it is a philosophical approach that requires changing the pervasive mindset within an organization towards […]

How to calculate and improve Machine Availability

Keeping equipment running efficiently requires managing a dynamic balance in uptime, run time, fully productive time, and a myriad of other factors. Get it right, and a finished product can be produced at the lowest cost and highest efficiency. Get it wrong, and plant performance suffers from unplanned downtime, unplanned maintenance, and a high failure […]

What is manufacturing capacity analysis and how to perform it

Manufacturers face a mountain of challenges to produce the goods we use in our lives. And each one must address these challenges with limited resources in the form of capital, skill sets, technological advances, and more. The managers who orchestrate this complex arena best look for ways to maximize the tools they have at their […]

Machine Utilization: Track and Improve equipment performance

Manufacturing is a costly endeavor. Labor, raw materials, indirect overhead, and capital equipment are all large cost centers, and optimizing them is a goal of any manufacturing company. But one thing stands out among those costly line items. While all these areas have room for process improvement, machine utilization rates can make or break all […]

Maximizing Production: Tips to increase Manufacturing Productivity

Most companies value the ability to enhance production plans. And the optimal for manufacturers is not investing in additional equipment while production capacity and productivity still increases. After all, the essence of manufacturing is producing goods, and modern operations are increasingly efficient in doing so. In this article, we will explore exactly what production capacity […]

OEE – Overall Equipment Effectiveness: A comprehensive guide

What is Overall Equipment Effectiveness (OEE)? Overall equipment effectiveness (OEE) provides a means to measure the percentage of productive planned manufacturing time. By measuring OEE, you gain insight into optimal productivity challenges and how to improve your manufacturing operations. How is OEE Used? Overall equipment effectiveness is the most widely used standard for measuring manufacturing […]

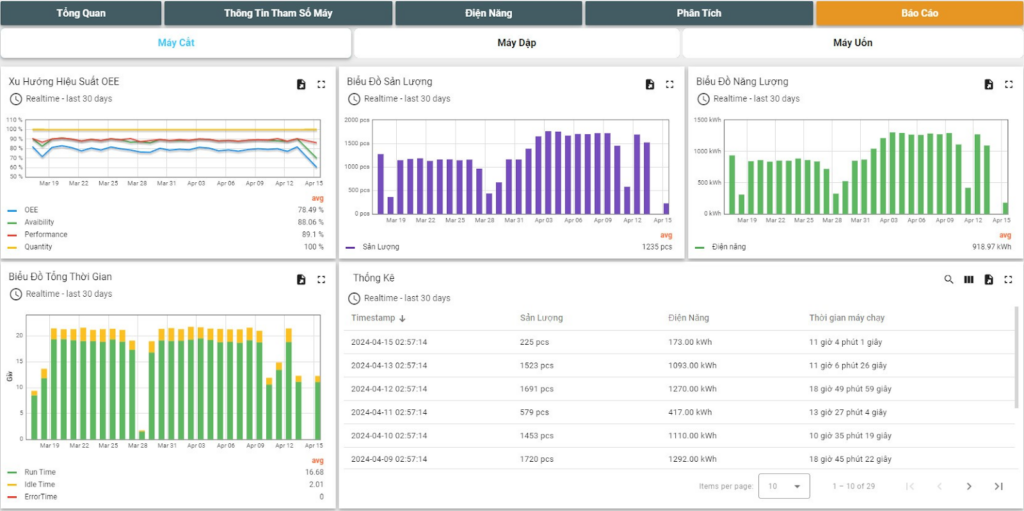

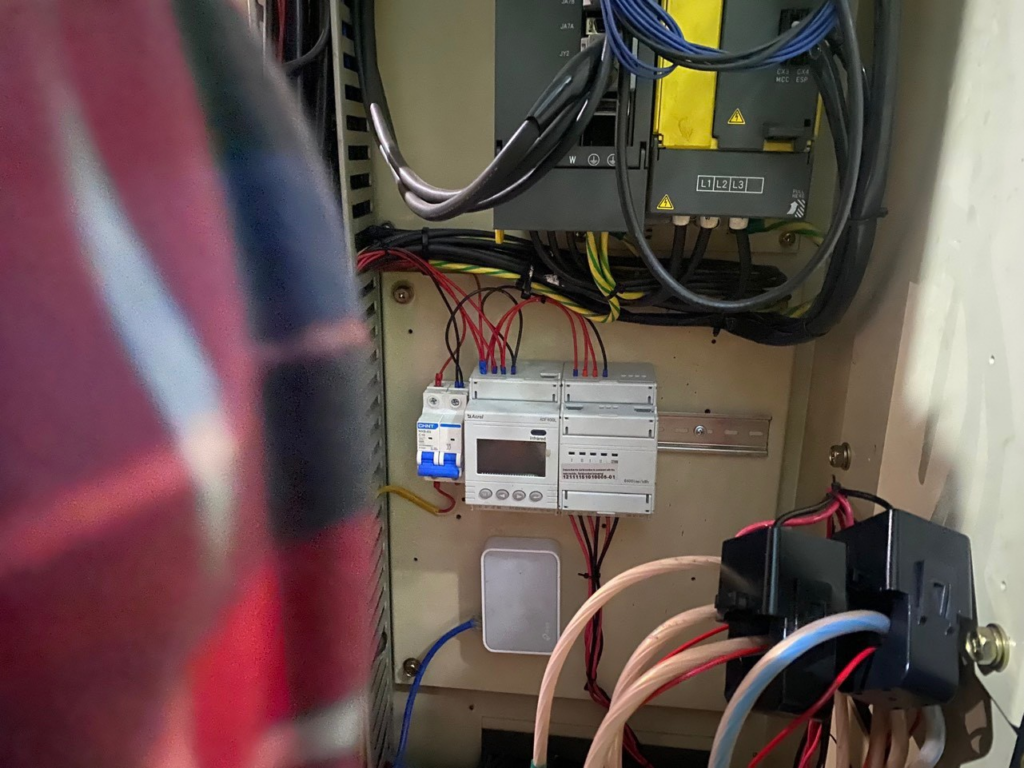

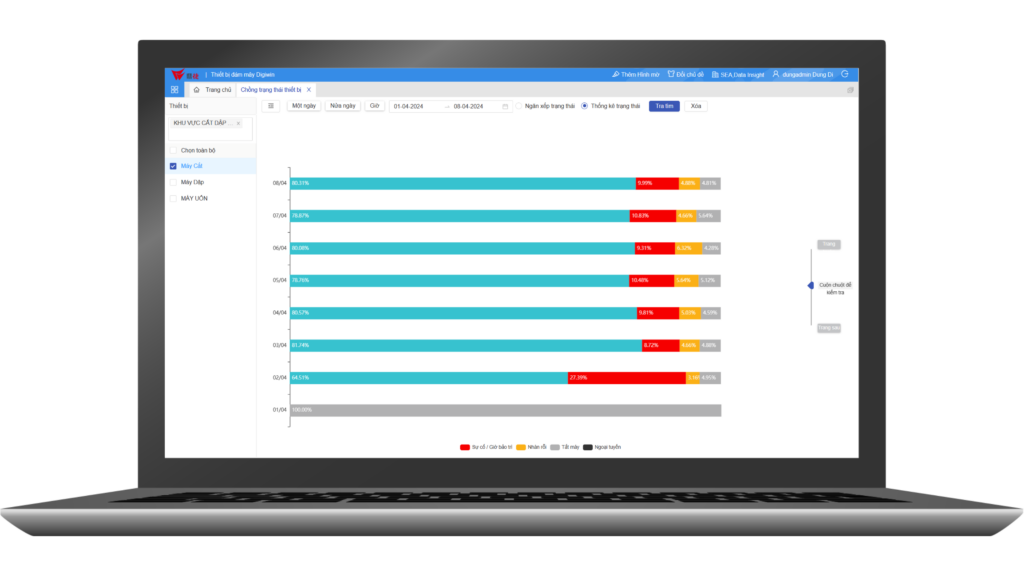

Measuring and Optimizing Machine Productivity

In industries that demand high precision, enhancing the productivity of production equipment is crucial to meeting standards and desired output levels. To monitor and improve the machine productivity on the production line, directly collecting data from equipment is the most effective approach. Let’s review important metrics such as production quantity, cycle time, production costs, and […]

Machine condition monitoring: Improving machine health and OEE

What is Machine Condition Monitoring? Machine condition monitoring is the ability to assess the health of a machine over a period of time. This can include things like its efficiency, since losses in efficiency may indicate an underlying issue. It also includes wear and tear on parts, performance indicators such as output of defective parts, […]