Oee software: How to track and improve productivity

Manufacturing operations can no longer rely solely on manual interventions and archaic tracking methods. In today’s data-driven world, software solutions have emerged as a vital tool for factory optimization. This blog will dive deep into the nuances of OEE software, its benefits, and why it’s a must-have for modern manufacturing units. What is Software for OEE? OEE stands […]

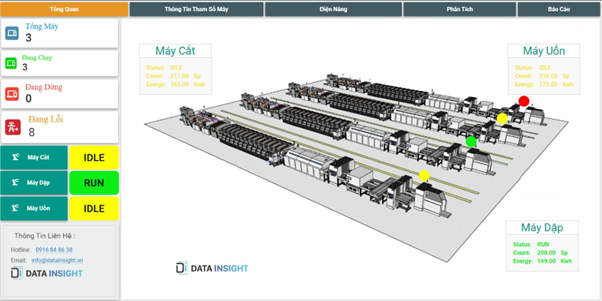

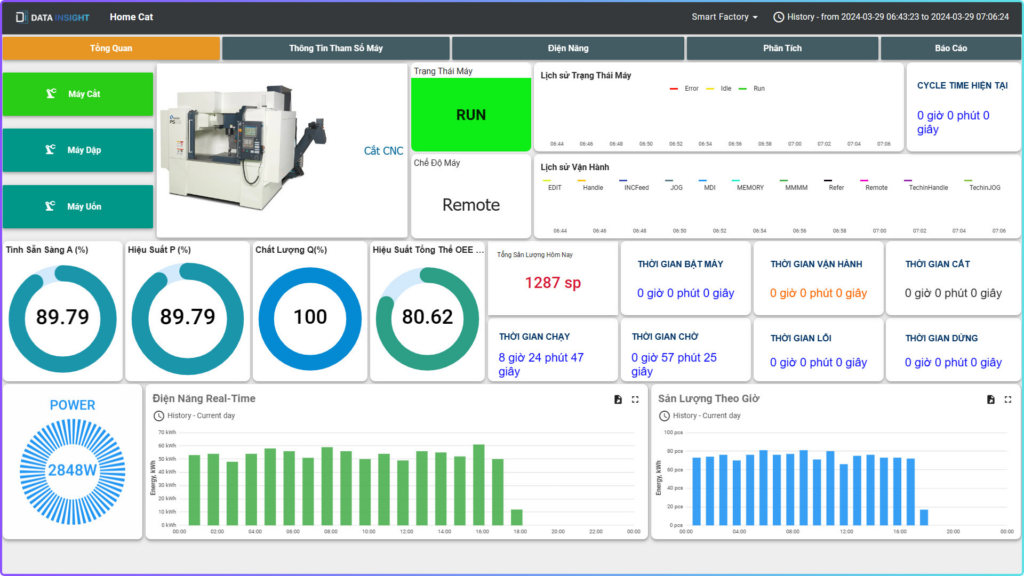

Visualizing Production Performance with OEE Dashboards

A manufacturing company is only as good as its equipment management. However, more importantly, it’s about how organizations utilize their equipment effectively. Without knowing the Overall Equipment Effectiveness (OEE) of manufacturing machines, companies risk losing ground in the highly competitive manufacturing environment. By collecting and analyzing OEE data, users can better understand how efficient their […]

HOW OEE SOFTWARE IMPROVES PRODUCTION EFFICIENCY

Overall Equipment Effectiveness (OEE) is a methodology that has been around for many years. It is a straightforward system that measures a machine’s performance and productivity. By factoring in variables such as downtime associated with changeover, breaks, off-quality part fallout, and others, OEE software can determine how productive an operation truly is by measuring the […]

Improve efficiency in your plant with OEE calculations

OEE’s role in manufaturing The Overall Equipment Effectiveness (OEE) plays a crucial role in enhancing manufacturing efficiency. OEE is a method used to measure and monitor the overall performance of production equipment and processes. By applying OEE calculations, you can identify causes of time or resource waste during production and improve efficiency to increase the […]

OEE: YOUR BUSINESS NEW FINANCIAL KPI

Overall Equipment Effectiveness (OEE) is often seen as a manufacturing metric. Yet it can be a financial key performance indicator for executives as well. Better still, instead of a lagging indicator showing what happened, you can turn it into a leading indicator of what will happen. You can then use it to drive the overall […]

7 STRATEGIES TO IMPROVE OEE

This article aims to provide a clear understanding of OEE and methods to enhance productivity in manufacturing, whether you are using OEE software for automated data collection and calculation, employing manual methods, or are new to OEE metrics

Difference between OEE, OOE and TEEP

OEE’s Defintion Overall Equipment Effectiveness (OEE), the most commonly used manufacturing metric to understand, measure, and improve current performance. To review, OEE is measured by combining a machine’s performance, availability, and quality. In this way, OEE helps you to identify potential losses and understand where your process is falling short. But OEE alone is just […]