How Cloud and SaaS make Smart Manufacturing Cheaper, Secure

The choice between using on-premise software and SaaS (Software-as-a-Service) is currently a hot topic for manufacturers. Here are some key points to help you better understand the benefits of SaaS and why many manufacturers are shifting towards this solution. Security Concerns and Solutions Previous Concerns In the past, many manufacturers were concerned that cloud-based software […]

What is cycle time? How to calculate and reduce cycle time

When it comes to production environments, it’s always a question of how much can be produced, how quickly, and at what cost. At the end of the day, how efficient are we? Cycle time is one of the best measures we can use to analyze the efficiency of a production process and allows managers to drill […]

Two trends in sustainable manufacturing

Sustainable manufacturing remains one of the most critical and influential topics within the industry. Nowadays, more and more people, from business leaders to environmental activists, are discussing greener and more efficient approaches to protect our planet. Choosing an environmentally friendly manufacturing path not only benefits the Earth but also opens new opportunities for businesses, helping […]

Why most Industrial IOT Implementations fail?

The IoT Revolution is picking up speed and as it does, it is changing the manufacturing world forever. The Industrial Internet of Things (IIoT) brings together machines, advanced analytics, and people . It’s the network connected assets and devices by communications technologies that results in systems that can monitor, collect, exchange, analyze, and deliver valuable […]

Why most Industrial IOT Implementations fail

The IoT Revolution is picking up speed and as it does, it is changing the manufacturing world forever. The Industrial Internet of Things (IIoT) brings together machines, advanced analytics, and people . It’s the network connected assets and devices by communications technologies that results in systems that can monitor, collect, exchange, analyze, and deliver valuable […]

How to identify and solve production issues with data analysis

Knowing how to solve production issues quickly and efficiently is a skill all manufacturing managers should possess. Though there are many strategies that exist to identify and fix problems, the starting point for eliminating the most severe shop floor issues is having an infrastructure in place to support the automated collection and standardization of production […]

The 6 core Technologies of Industry 4.0

Innovation, in manufacturing in particular, has exploded, thanks to Industry 4.0. The term was coined to reflect the trend towards the use of technology, automation, and data acquisition in manufacturing. Companies can now integrate their operations vertically and horizontally, leveraging previously untapped data analytics to get a handle on every aspect of their production cycle. […]

What is Takt Time? How to calculate and reduce this key metric

The Industrial Internet of Things (IIoT) is transforming how manufacturing companies measure and improve processes. By using a machine data platform, companies can rapidly realize fast ROI and unprecedented improvements in efficiency and productivity. But industrial IoT and machine data platforms alone aren’t magic wands that can be waved to create new value. While they […]

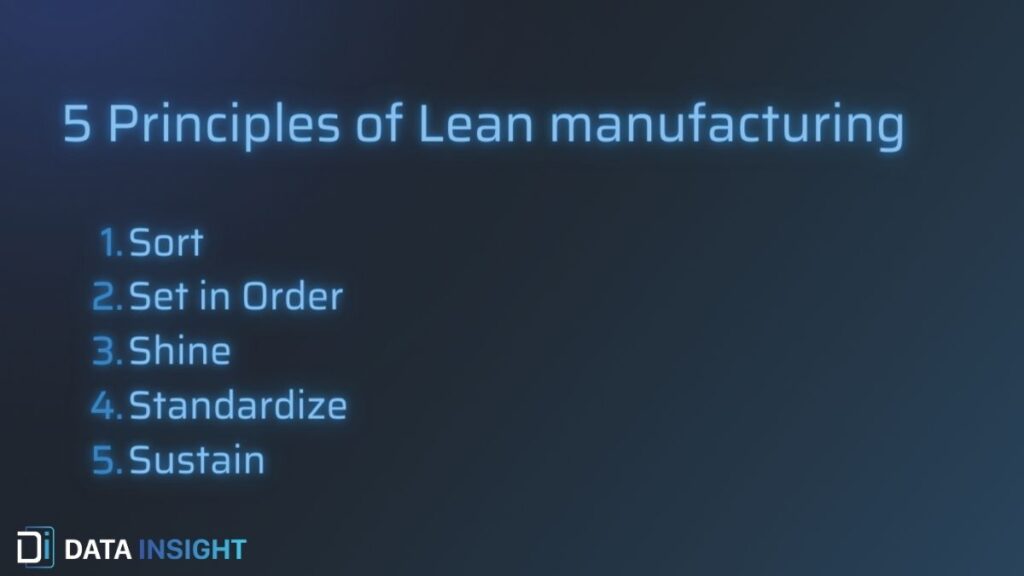

Lean manufacturing: The Principles, Wastes, Benefits, and Tools

What is Lean Manufacturing? Lean manufacturing is a philosophy founded on a strategic approach to continuous improvement and sustainability through the holistic elimination of waste and inefficiencies throughout an organization. Lean manufacturing is more than following a set of rules—rather, it is a philosophical approach that requires changing the pervasive mindset within an organization towards […]

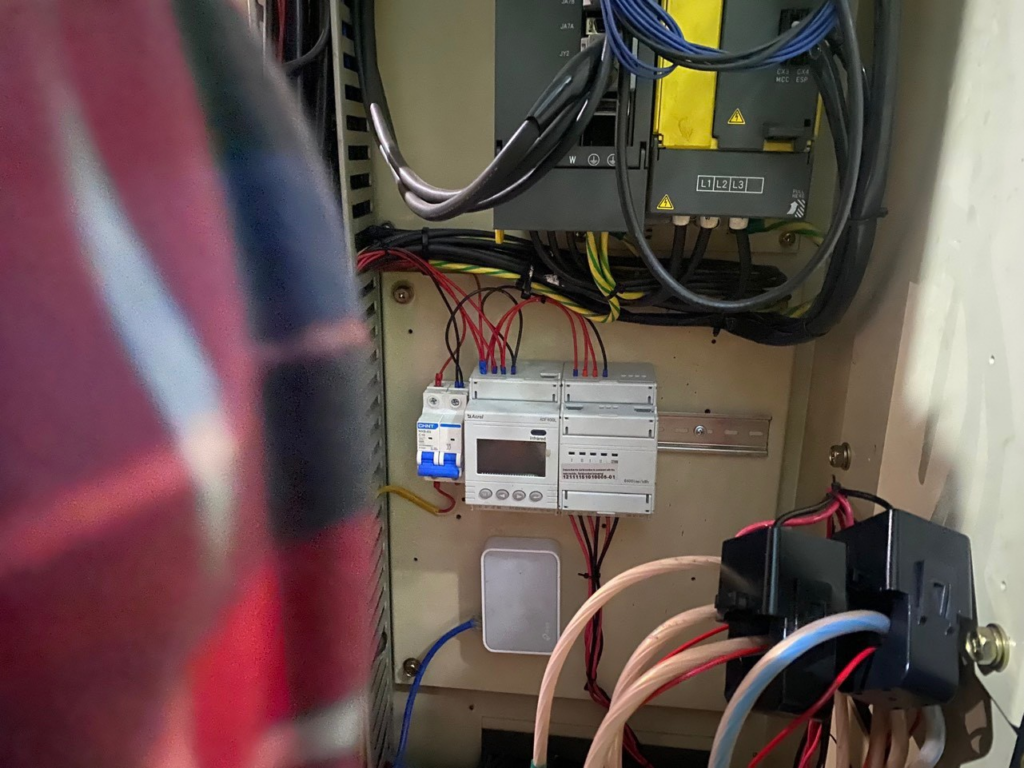

Measuring and Optimizing Machine Productivity

In industries that demand high precision, enhancing the productivity of production equipment is crucial to meeting standards and desired output levels. To monitor and improve the machine productivity on the production line, directly collecting data from equipment is the most effective approach. Let’s review important metrics such as production quantity, cycle time, production costs, and […]